Ragic All-in-One Retail Management System Helps nozzle quiz Cut Significant Work Hours

| Company Name | nozzle quiz

|

| Scope of Business | Taiwanese streetwear brand selling apparel and accessories across Taiwan, the UK, US, Hong Kong, Singapore, Malaysia, and more |

| Industry | Fashion / Streetwear Retail |

| Benefits of Implementation | - Reduced inventory update workload from a full night every two weeks to a quick monthly check - Eliminated manual Excel updates and repetitive catalog communication with distributors - Cut barcode creation time from ~20 minutes per item to direct automation, saving dozens of labor hours per season - Automated order processing for distributors, removing hours of manual quoting work per order - Centralized all product, order, and production data into one Ragic system, ensuring consistent and accurate information across internal staff and distributors |

| Applications | Inventory, Production, Sales Order, Employee Management |

| Subscription Plan | Professional plan |

| Scale of Use | Around 7 internal users and multiple external distributors accessing shared reports and order forms across different countries |

nozzle quiz: A Streetwear Brand in Need of a Better Inventory System (or honestly, just a system)

If you work in fashion retail, you know the drill. Endless SKUs, every size and color with its own code, endless catalog updates.

“Did the distributor get the latest stock info?”

“Are we even sure of our own numbers?”

“Did I just oversell that top-selling product?......”

And just when you finally get organized, a new collection drops. So all of that? Repeat. Plus the newest batch. Just keeping stock accurate can feel like a full-time job, unless you have a solid inventory system.

Then there’s the sales side. Maybe you sell on your own site, maybe through distributors, maybe on consignment. Each channel needs its orders handled a little differently, and those orders have to be managed carefully or you’ll throw off your inventory. On top of that, everyone wants the newest catalog right away. It’s a lot to juggle.

For nozzle quiz, a Taiwanese streetwear brand founded in 2017, this was everyday life. They started with socks and grew into shirts and pants, now selling across Taiwan, the UK, US, Hong Kong, Singapore, Malaysia, and more. The name blends “nozzle” (the knitting machine part) with “quiz” (a nod to curiosity and creativity). Their philosophy: functionality can be fashionable. Socks might be the most practical part of an outfit, but the right knit turns them into a statement piece.

Behind the cool designs, though, the workflow was chaos. Everything was run on manual Excel files and a local POS system called ONE-POS. It only worked on one computer, reports were limited, and inventory had to be updated by hand. Every two weeks someone lost a night to spreadsheet duty just to keep stock halfway accurate. It was honestly soul-crushing.

Errors? Back then, they felt unbeatable. With consignment sales each running on a consignment partner’s own system and no central data, if the numbers didn’t match, good luck finding out why.

That POS system was another headache entirely. Fan, one of the owners who ended up building their Ragic system, hated that once you created a product record it was locked forever, even if you made a typo. There was no way to correct or delete it, so a single mistake lived in the system like a bad tattoo.

Production management was another black hole. Every season meant manually creating spec sheets in Excel, product details, marketing copy, barcodes, the works. Files got lost, versions got mixed up, and different distributors sometimes ended up with slightly different info. Imagine trying to run a fashion brand when even your own partners can’t agree on the product details.

It was obvious. nozzle quiz needed a better system. Designing fun, bold apparel was the exciting part of the job. The manual spreadsheet updates, along with all the errors, definitely weren’t.

Why Ragic?

In 2023, nozzle quiz started using Ragic. Fan didn’t even know what “no-code” meant at the time.

He had tried Kintone first. It looked nice, but it didn’t feel intuitive or familiar. Ragic did. Fan had years of experience in Excel, and Ragic felt like Excel with superpowers—everything he knew, minus the problems

The goal was: cut down the endless manual work of updating spreadsheets to keep stock levels in sync and replying to distributors about the newest catalog or inventory changes. They needed one system easy to learn enough that could serve everyone: from traditional manufacturers with staff who aren’t very digital, distributors spread across different countries, and of course, their internal staff. With Ragic’s ease of use, they got it. Distributors can now access all the information they need directly in Ragic, without any extra cost on Nozzle Quiz’s side.

Since Ragic serves as their single source of truth, everyone sees the same up-to-date data at all times. It keeps things accurate, transparent, and effortless for everyone involved.

Customer support sealed the deal. Fan likes straight answers—yes or no, what’s possible and what’s not—so he doesn’t waste time chasing a workflow that won’t work.

“The customer support is outstanding. I can’t praise them enough. I’ve never experienced service this good.”

So what do they use Ragic for?

Managing Products and Everything Around Them

Products are the heart of retail. The details? Endless. Every size, color, promo photos, material specs, stock level. Previously, each new launch meant another Google Drive link for distributors, packed with catalogs and updates. Soon there were v1, v2, even older files (it happened, a promotional picture of the season 2 years ago) that slipped through as “the latest.” Distributors would text, “Is this the newest one?” and someone on the team had to stop, check, and reply over and over again. At first it felt like part of the job, until they realized it was just unnecessary work.

Ragic changed that. Now there’s one Product Master Sheet that holds everything. Their wholesale distributors open a single link already included in their contract, and instantly see the products available to purchase, promotional images, and specs. Grouping Report combined with the appropriate Access Rights Configuration makes this possible: External Users like their wholesale distributors can view only the fields chosen to be shared without logging in, while Multiple Versions allow internal staff to access private details like supplier info or cost. All integrated at the same system, sharing the same data set, while maintaining data privacy.

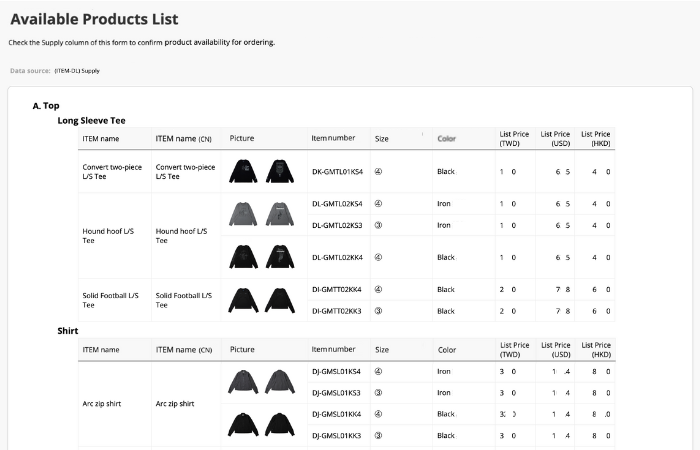

What the distributor sees:

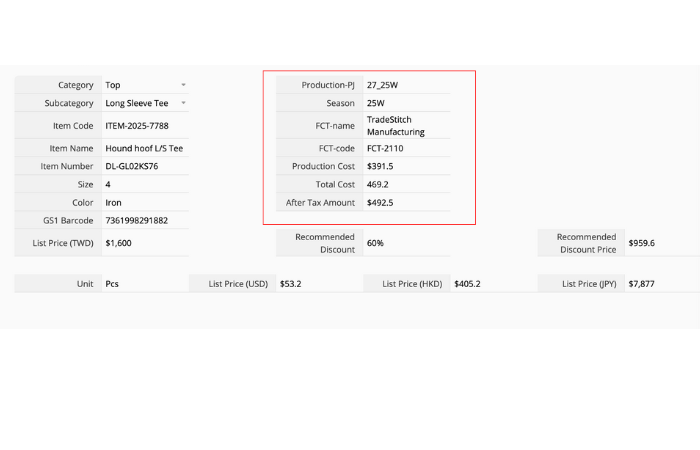

What internal staff can access, with the same set of data:

One source of truth for the team and every distributor. No scattered files, no endless back-and-forth. Just one link that keeps everyone on the same page.

Another thing they manage to do with Ragic is handling barcodes for their wash tag and hang tag. Before this, they generated the barcode manually with Adobe.

“Before, laying out a barcode took about 20 minutes per item. With 20 products in a season, that’s hours of work. I’d make a big table, then cross-check manually. Two people had to check: I’d finish, you’d check, then you’d check again, and sometimes errors still slipped through. Adobe generates the barcodes, but if you mistype the product code, you wouldn’t know—it still creates a barcode, but it could be wrong. And if the goods have already been sent to the vendor, you’d have a mismatch between the system and the actual product—big problem.”

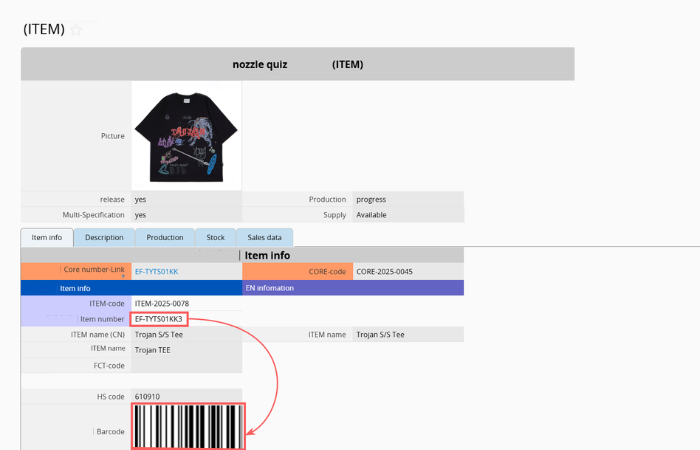

Product Data Sample with Barcode

“Now with the Ragic Barcode Generator, I just select, print, and give it a quick check. The data comes straight from the system, so it’s reliable and saves a huge amount of labor.”

Different Types of Customer Orders, Yet, Manual Works Eliminated

nozzle quiz juggles all kinds of orders. Big-volume B2B deals and everyday B2C sales—and Ragic keeps the whole thing painless.

B2B

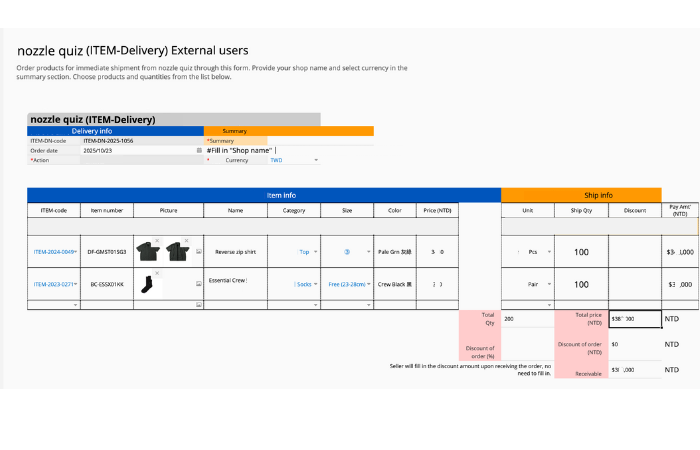

Their distributors and consignment stores buy in bulk and expect special pricing.

Before? Someone on the team had to pull up Excel, check stock, calculate the wholesale discount, build a quote…every single time.

Now? Distributors fill out a Ragic Web Embed Form to place order, with their total directly calculated, that connects to the Product Master Sheet so only in-stock items show up, and the order lands in the system automatically. Hours of quoting work, gone.

How customer places orders

B2C

Shopee orders, website orders—it all gets exported once a day and dropped into Ragic.

With every sales order in one place, inventory stays spot-on and the team finally sees the big picture: trends, totals, what’s moving and what’s not.

International sales

Nozzle Quiz has automated nearly every pain point that comes with cross-border selling, one by one.

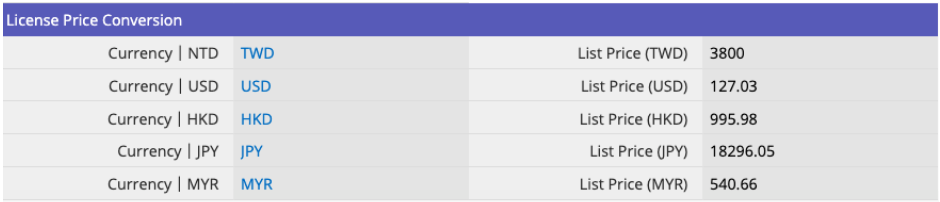

1. Exchange Rate Automation

Remember searching for exchange rates on Google and updating every formula in Excel, not just for different countries but every time the rate changed (which is basically always)? nozzle quiz does, and they definitely don’t miss it.

Now, their sales orders run on Ragic with the Exchange Rate Field. They can easily update rates regularly, and the correct rate is automatically applied when customers place orders, greatly improving efficiency.

Exchange Rate Field Application

It might seem like a tiny chore, tweaking a formula here, double-checking there. But once those micro-tasks disappeared, the team realized how much mental space they’d been spending on spreadsheet babysitting.

2. Customs Declaration Simplified

Each product in their database already includes an HS code — an international classification number customs requires for exported goods. So when they need to declare a shipment, there’s no scrambling to look up codes or retype product details.

They can instantly generate a customs invoice straight from a sales order. The invoice includes HS codes, currency, and total amounts, Excel format, ready to hand print and hand-off to logistics providers like FedEx or UPS.

Fan mentioned that most e-commerce sales orders don’t include HS codes, which means staff would normally have to look them up manually for every shipment. A task that could take 15–25 minutes per order, depending on the shipment’s complexity and the staff’s efficiency.

But with everything stored in Ragic, they have a dedicated HS Code Sheet, and each product is linked to its code when the sales order is generated. Now, the automation takes care of it entirely, so the team doesn’t have to think about it at all.

3. Shipping Cost Tracking

They also track international shipping costs directly in Ragic. Overseas orders are rarely straightforward. They often come with extra charges like remote-area fees, fuel surcharges, customs duties. So the team records what they charge the customer and what they actually pay the logistics company, then checks whether the cost-to-order ratio looks normal.

Watching that trend helps them decide if they need to adjust what they charge international customers in the future. This process used to live in an Excel file that staff often forgot to update, so comparisons were rarely done and any shortfall quietly came out of the company’s pocket.

3. Accurate Inventory Tracking

Inventory updates automatically, and distributors and consignment resellers always see real-time stock.

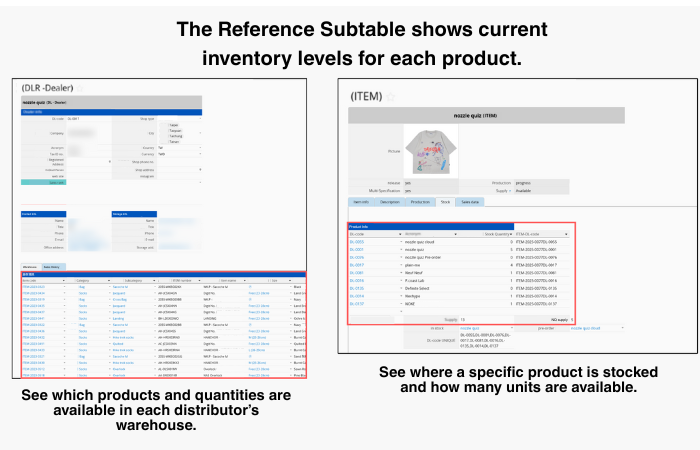

Since nozzle quiz also needs to manage their distributors’ inventory, they created a Distributor and Warehouse sheets to manage distributor and warehouse information as well as stock levels. Each distributor is treated as a separate warehouse with its own unique ID (e.g., DL-0001). In addition, even though all physical stock is stored at the company, they can categorize warehouses by function and set up virtual warehouses, such as “Cloud” or “Pre-order,” for purchased-but-not-yet-arrived or pre-sale items in development.

Each Warehouse ID combines with the product number from the Product Master Sheet to generate a Warehouse Stock Number, which tracks product quantities in each warehouse. Stock movements are managed through four dedicated sheets—Outbound, Inbound, Transfer, and Stocktaking.

When users record a quantity change in any of these sheets, an action button (like Confirm Sale) automatically updates the corresponding warehouse’s stock. Since the Inventory Sheet links to both the Distributor & Warehouse and Product Master sheets, reference subtables under each sheet show the remaining stock for every product across all distributors. Likewise, under each distributor, all products they currently have in stock are displayed in the reference subtable.

Inventory check and update that used to take a whole night every two weeks is now reduced to a quick manual check once a month—only when something goes wrong or stock levels fall below the safety threshold.

4. Building Better Employee Management in a Small Team

Fan thinks nozzle quiz adopted Ragic at just the right moment when the team was around seven people. With a small team, the friction of introducing a new tool is manageable. Let’s be honest: any new tool brings some friction, but starting small makes it easier to adapt.

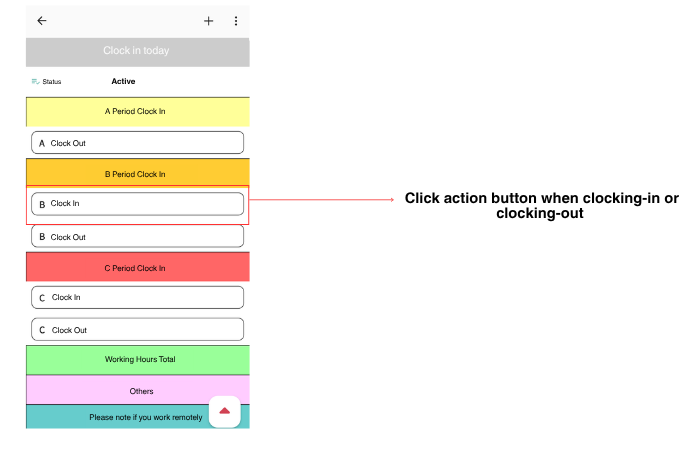

But the small team wasn’t the only reason adoption went smoothly. A big part of it came from employees seeing firsthand how much Ragic improved their work life. Fan implemented it for employee management, including Clock-in/Clock-out and Leave Requests, all easily submitted through the Ragic Mobile App.

Clock-in and clock-out in mobile app

Ragic also brought transparency and consistency to daily operations. Every employee writes their SOPs and stores them in Ragic, preventing lost files and ensuring consistent training. If someone leaves, the next person isn’t thrown into the dark, everything they need is clearly documented. The same goes for when someone is on leave; the person covering for them isn’t completely lost because the SOP is already in the system.

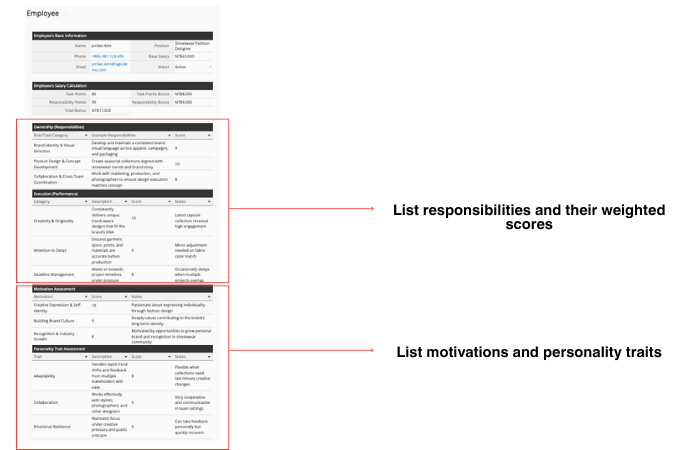

Another thing made possible by Ragic is the Internal Contribution-Based Payroll System that Fan built from scratch to match his vision—something standard HR systems might not even be able to make possible.

In this system, every employee has their own entry that links tasks to key performance indicators (KPIs). Each task is assigned a “weight” in points, which transparently shows how much that task contributes to the company. The points are then used to calculate the employee’s contribution that directly affects their salary.

This setup brings full transparency. Employees can see which tasks are the highest priority, how much time to spend on them, and exactly how their work impacts the business. No more guessing, no vague “this might be important.”

It also eliminates disputes. Employees can’t claim, “This isn’t my job”. Everything is tracked in the system. And when a task is completed, they know exactly what incentives they earn. The result is a clear, fair, win-win system for everyone.

The Value of Clear, Integrated Data

For Fan, clear data is a form of clear communication.

“As long as they understand the product and the data is clear, that’s enough. I value having clear initial data. If all the answers are already there, they don’t need to talk to me. I like a model where communication isn’t necessary—it’s like a website: place the order and that’s it.”

That’s why having all data live in one tool is also necessary for Fan. When information lives in different tools, it’s easy to forget to update it. For example, their Product Master Sheet used to be in Excel too, and they often skipped updating it. Once these sheets were moved into Ragic alongside other data, the mental barrier disappeared. Now they can filter, view, and add information in one place with a few clicks.

Fan believes everyone has a mental map of where their data lives. Switching tools feels like taking an extra “walk” to reach it. When the data is already in the one system you use every day, that extra effort—and the subtle psychological friction—vanishes. Even if the actual time saved is small, the friction becomes noticeable when juggling many tasks. Keeping everything in a tool that can handle all-round operations, and integrate with other systems when needed, like Ragic, reduces that friction and makes people more willing to keep records up to date.

Category: Case Studies > Retail